The field layer of remote measurement and control (RTU) system should be diverse and should move forward according to the development of demand and technology. As the field layer of the measurement end of the remote measurement and control system, the situation of each industry is very different. Generally, a single measuring instrument is connected to RTU to form multi-point I / O concentration. It is installed on or near the site. It can transmit and receive wireless signals through data transmission radio and connect to the network. Some industries have developed to transmit and receive radio waves on a single transmission, so that multiple converters and monitoring stations form a local area network. RFID RFID technology enables smart cards to be attached to objects, which can transmit and receive radio waves, so as to "connect things with things", which is also the basis of the Internet of things.

Development and application requirements of remote measurement and control system

In a broad sense, remote measurement and control system includes local area network, metropolitan area network and inter city network (WAN). The communication distance ranges from a few kilometers to hundreds of kilometers, thousands of kilometers, or even more. The region spans within and between cities, to land and ocean. In a narrow sense, the measuring points are scattered (1-2km), mainly focusing on measurement and data acquisition, with less and simple control (pump start and stop or single loop adjustment), that is, the detection is scattered, the data processing and display operation are centralized, the data processing capacity is large, and there are many ways of data transmission media.

For the data from the field, some remote measurement and control systems require continuous measurement of data, while others require data transmitted regularly. Therefore, the wireless transmitter can save energy and achieve low power consumption due to intermittent work, so it can be powered by battery.

RTU shall have at least the following two functions:

Data acquisition and processing

Data transmission (network communication)

Many RTUs also have PID control function or logic control function, flow accumulation function, etc.

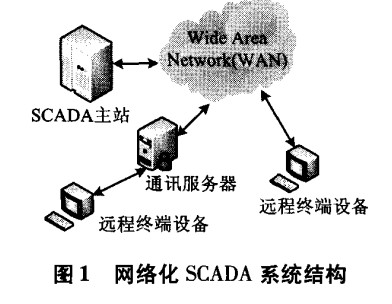

As a centralized monitoring station is formed in the network, SCADA software (supe RVI sory cont rol and Da t acquisition) is produced. The measurement and control system is also called SCADA system.

SCADA system software is divided into two parts: man-machine interface software and data acquisition software. The corresponding software can be written as HMI / SCADA software. The corresponding SCADA system hardware is simply divided into man-machine interface equipment and data acquisition equipment. In the case of wireless communication, there is also communication processing front-end computer and man-machine interface equipment to monitor the existing central database in the station. For example, the configuration of a SCADA system dispatching center is: server, wide area backbone network, workstation and communication front-end machine.

SCADA software has become an independent product, also known as configuration software in the industrial control industry. It mainly solves the problem of man-machine interface, and expands to configuration control strategy, establishing real-time database, communication and networking, providing various I / O drive systems, etc. Its main functions include: application manager, graphical interface development / operation program, real-time database system configuration / operation program, I / O driver, etc. Other functional components include: general database interface (odbe interface) / running program, control strategy editing / generation component, practical communication program component, etc.

In terms of standardization, I E C611 3 1 - 3, OPC, TCP / TP, etc. are adopted.

After the SCADA software runs, it can complete the following tasks: check the real-time data and process screen on the site; Automatically print various real-time / historical data reports; Freely browse various real-time / historical trends; Get and handle various process alarms and system alarms in time, intervene the production process manually when necessary, and modify relevant parameters or states (manual operation); Computer networking with the management department to provide real-time and historical data for the management department.

Field instrument and RTU

The remote measurement and control system provides various detection data by field instruments, and the field conditions are different, so there should be a variety of instruments for users and designers to choose.

● Industrial Wireless Technology (LAN) developed in recent years is mainly represented by Shenyang Institute of automation, Chinese Academy of Sciences, and proposed by China's National Standardization Management Committee. It has become an International Standard Industrial Wireless Network WIA (wireless networks for industrial automation), which adopts mesh (Network) routing structure, whole network TDMA mode and low energy consumption technology with battery, It has WIA wireless communication module, which is integrated with temperature module, pressure flow module, liquid level flow module and other intelligent wireless modules - field instrument (each instrument has an antenna), and WIA wireless gateway, which is used for wireless communication with field instruments and data collection, and then connected with the wired system of the central control room through serial ports such as Ethernet. It can also integrate remote transmission wireless communication GPRS module DTU.

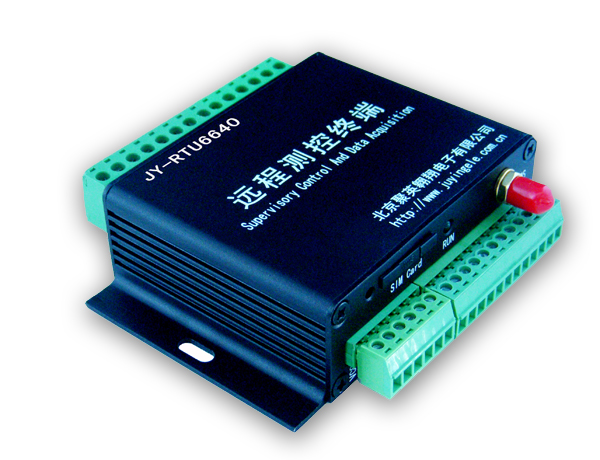

● RTU remote terminal unit has been used in oil fields, urban gas pipelines, water sources of waterworks and other places for more than ten years. It is a mature product, which meets the connection of several to dozens of input and output signals. The detection instrument is a special or general analog instrument, and the output signal can be analog quantity and switching quantity, Access to data transmission radio station through modem. This mode is used for the initial concentration of scattered measuring points on site, which is convenient for 1:1 wireless transmission.

● Fieldbus Technology (more than 20 kinds of fieldbuses, including Hart), which provides digital field instruments, has priority as the basis of remote measurement and control system. In the original design, the communication medium is wireless, but only as an extension of distance. Now there are remote input / output devices. How to form a wireless LAN is still in the process of research and development.

● using PLC controller as RTU substitute is also a feasible scheme in many sites, and there are many engineering examples.

● RFID technology has been gradually applied in factory management and logistics industry. It is a non-contact movable intelligent ID card with remarkable functions in identification, tracking and search. It will be the basic technology of the Internet of things and a field that can be developed by remote measurement and control system.

In short, the field layer of remote measurement and control system should be diverse, and should continue to move forward according to the development of demand and technology.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts