Aquaculture industry, as an important national meat variety, with the increase of demand in recent years, the problems of low output and product difference of traditional free range aquaculture have become more and more prominent. At the same time, the problems of disease prevention are difficult for high economic aquaculture varieties, which has become the main resistance restricting the development of aquaculture.

In this regard, it is necessary to speed up the construction of modern aquaculture system, improve the intellectualization, digitization and automation of aquaculture, strengthen the application of Internet of things, wireless communication, big data, cloud computing, artificial intelligence, mobile Internet and other technologies in aquaculture industry, improve the environmental monitoring ability of aquaculture waters, strengthen the regulation ability of waters, reduce disaster risks and hazards, and improve the quality and quality of aquatic products.

The intelligent aquaculture monitoring system based on the Internet of things collects the environmental parameters of aquaculture waters and the energy consumption of oxygenation pumps, circulating pumps, feeders and other equipment, including water temperature, dissolved oxygen content, pH value of water area, turbidity of water quality through sensors, flow meters, wireless acquisition terminals, intelligent valves and other equipment, based on the conditions and types of aquaculture waters through the Internet of things, Internet, wireless communication and other technologies Ammonia nitrogen and other nutrient content and other parameters, as well as the total power consumption, voltage, current, power and other data of each water pump. Through mobile app, computer web page / APP, monitoring screen and other information terminals, we can grasp the information of aquaculture water area at any time, check and receive the abnormal situation early warning information of aquaculture water area in multiple ways, and remotely linkage control the equipment to stabilize the water environment and ensure that the water environment is suitable for fish, shellfish, shrimp, crab Growth demand of aquatic products such as algae.

1. Environmental monitoring equipment

| Equipment name | purpose |

| Dissolved oxygen sensor | Measure dissolved oxygen content in water area |

| TriE Conductivity Sensor | Measuring the conductivity of water quality |

| Water quality pH sensor | Measuring the pH value of water quality |

| Water temperature sensor | Measure water quality temperature |

| Residual chlorine sensor | Measure the residual chlorine value of water quality |

| Turbidity sensor | Turbidity data for measuring water quality |

| Illuminance sensor | Measuring illuminance of water area |

| Ultrasonic liquid level sensor | Measure water level |

| Input type liquid level sensor | Measure water level |

| Flowmeter | Measuring water flow |

2. Energy consumption monitoring equipment

Lora wireless mode is adopted to collect the data of water meter / electricity meter scattered in each room / dormitory area, and then transmit it to the intelligent monitoring host, which will upload it to the livestock and poultry monitoring platform through 2G / 3G / 4G or Ethernet WiFi for data monitoring and recording.

| category | Communication mode | Function description |

| Lora intelligent water meter | Wireless Lora communication; | Industrial Lora water meter sub machine |

| 470-510mhz band; | ||

| Up to 3km wireless transmission; | ||

| Power supply DC24V; | ||

| Valve control; | ||

| Water meter data acquisition; | ||

| With IP68 waterproof high strength die cast aluminum shell | ||

| smart meter | RS485 communication; | Standard Modbus protocol; |

| Voltage / current / power / electric quantity / frequency and other electrical parameter acquisition | ||

| Lora wireless transmission terminal | Wireless Lora communication actinide | Industrial grade Lora transmission sub machine; |

| 470-510mhz band; | ||

| Up to 3km wireless transmission; | ||

| Power supply DC24V; | ||

| Meter data acquisition; | ||

| 35mm guide rail installation; |

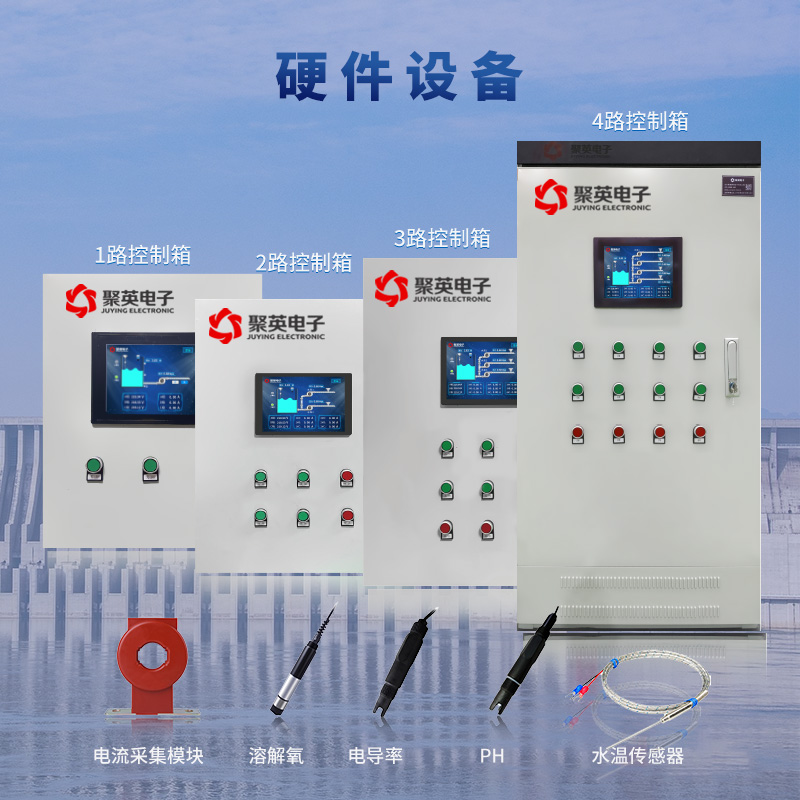

3. Control equipment

Intelligent control cabinet

Function description

collect the temperature data of aquaculture water area in real time

collect dissolved oxygen content, conductivity and pH data of aquaculture waters in real time

support the control of local oxygenation pump, circulating pump, feeder and other equipment

support the working current detection and feedback of multi-channel control equipment

support local sensor data display

support local equipment working status display

support local policy configuration

support local parameter adjustment

support remote control and telemetry

4. Early warning equipment

5. Cloud platform

Juying smart aquaculture cloud platform provides multi terminal software such as Android / Apple mobile app, computer monitoring platform and wechat monitoring platform, which can communicate with the intelligent control cabinet through 4G / network to realize the remote control of aquaculture waters. Automatic operation process parameters support remote modification, real-time effectiveness and offline execution, and support multiple alarm modes such as app, wechat message, telephone and SMS. The cloud platform has the function of data recording and analysis, which is convenient for record backup, emergency analysis and behavior tracing.

1. Configuration scene monitoring

The aquatic monitoring platform can provide a software interface according to the distribution of aquaculture, distinguish the location, layout and location of each monitoring point on the interface, and arrange according to the actual layout, so as to realize the vivid image of the monitoring interface and provide convenience for the actual monitoring.

2. Single pool real-time monitoring

● provide real-time information on water temperature, dissolved oxygen, illumination, pH value and conductivity of each monitoring point;

● provide historical data query, support data query in any time period in the past, and provide data basis for some emergencies.

● provide historical music view. By observing the change trend of a certain period in the past, we can summarize the corresponding change law, from which we can summarize some valuable experience.

● provide real-time alarm function. When any parameter reaches the alarm condition, the monitoring software will provide sound and corresponding value flashing alarm to provide alarm prompt for relevant management personnel.

3. Intelligent logic control

Through the PLC intelligent automatic control function of the host of the monitoring cabinet, the intelligent and automatic regulation of the environmental regulation system, feeding system, energy saving and consumption reduction system in the aquaculture water area and the unified regulation system of the whole field can be realized. All regulation parameters can be set and adjusted remotely through the mobile app / computer monitoring platform, which takes effect in real time.

4. Centralized monitoring of equipment

Through the large screen monitoring platform in the management center, the staff can view the monitoring and operation data of all subsystem equipment in the aquaculture water area at the same time for unified display.

5. Monitoring data alarm

When the environment monitoring and energy consumption monitoring system has collected abnormal data such as water temperature, liquid level, pH value, dissolved oxygen content, voltage, current and power, the monitoring platform automatically sends various alarm such as sound warning, APP message push, WeChat official account message, active phone call, SMS content alarm, etc., so that the staff can handle the accident in time and prevent the hidden trouble caused by missing report.

6. User rights management

According to the management requirements of different aquaculture waters, the designated equipment has different permissions:

management authority: equipment information management authority, delete equipment authority, control authority, sharing authority, equipment internal parameter configuration authority, cloud policy control configuration authority.

editing authority: equipment information management authority.

operation authority: the operation authority to remotely control the equipment.

read only permission: view the real-time status of the equipment, and view the historical data, curves and statistical reports of the equipment.

7. Data curve monitoring

The cloud platform automatically records the sensor data and control data detected by the equipment once a minute, which can be displayed by curve query, or viewed by downloading and exporting excel table data. It also supports the automatic sending and receiving of backup data every day.

8. Video surveillance

The platform supports access to network cameras such as Hikvision / fluorite cloud, and supports synchronous display of video monitoring and data interface. When feeding, aerator and other equipment are remotely controlled, real-time action feedback can be obtained through video monitoring.

9. Pump station regulation

Pump station monitoring

Through the monitoring platform, the staff can monitor the working status, working voltage and current data of the oxygenation pump, circulating pump and other pump stations in real time, and remotely and manually control the start / stop of the pump station;

Liquid level monitoring

The monitoring platform displays the real-time data of the liquid level in the aquaculture water area. When the liquid level is at the low water level, the pump will be automatically started to supply water, when it is at the high water level, the pump will be automatically stopped, and when the water level is ultra-low, the remote alarm will be sent to the staff;

Two pumps work alternately

The aquaculture water area has working pump and standby pump. When two or more pumps work, the pump station will be automatically switched regularly to protect the pump station unit and prolong the service life;

Pump station protection

By monitoring the start-up and stop state of the pump station and setting the protection of working voltage and current, the pump will be automatically stopped when there are abnormal conditions such as phase loss, overpressure and overcurrent. At the same time, the remote alarm will be given to inform the staff to deal with it in time.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts