1. Introduction

Seawater is a highly corrosive electrolyte. Offshore steel structures are in the corrosive environment of the sea, and the damage is very large. The corrosion of marine environment is one of the important problems accompanying marine development. The world's annual economic losses caused by corrosion amount to US $600 billion to US $1200 billion, accounting for 2% ~ 4% of the sum of national GDP, which is six times the total losses of comprehensive natural disasters (i.e. earthquakes, typhoons, floods, etc.). Due to the particularity of marine environmental corrosion, the main hazards are: huge waste of resources, materials and indirect energy; Obviously shorten the service life of materials; The hidden danger of disastrous accidents may cause personal casualties and huge economic losses; Pollution of the marine environment. Steel structure is more and more widely used in seaport engineering because of its excellent physical, mechanical and construction performance. Monitoring the corrosion status of marine steel structure is one of the important work to ensure the normal operation of seaport engineering, eliminate potential safety hazards, reduce or even eliminate accidents, so it is very important.

Corrosion monitoring is an important part of marine steel structure anti-corrosion, but it has not been paid enough attention for a long time. In recent years, the corrosion problem of offshore steel structures in China has become increasingly prominent. The serious economic losses and even safety accidents caused by corrosion make people feel more and more difficult. When people try to find an effective way to prevent corrosion, corrosion monitoring, as the basic work of anti-corrosion, has attracted people's attention. Marine corrosion is a gradual process. Due to the discontinuity in time, the conventional detection will bring the problem of untimely alarm. Only continuous automatic monitoring of corrosion state can fundamentally solve this problem. The remote monitoring system based on GPRS DTU provides great help to solve this problem.

2. System composition

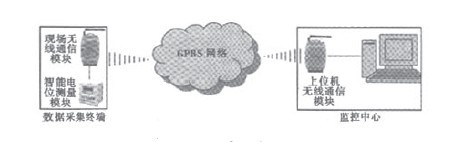

With the development of wireless communication technology, it provides strong technical support for corrosion monitoring. General packet radio service (GPRS) is a new data transmission technology. Taking the GPRS service of the national public mobile network as the transmission means, it greatly reduces the network construction cost of the system, with high reliability, wide network coverage, convenient distribution, simple capacity expansion, fast network formation and low maintenance cost. Through GPRS service, the data acquisition terminal equipment can connect to the host with the help of mobile wireless communication network for data exchange. As shown in Figure 1, the corrosion monitoring system based on GPRS is mainly composed of three parts: data acquisition terminal of telemetry station, monitoring center and GPRS transmission network.

2.1 system function and principle

The function principle of GPRS intelligent remote telemetry system is that the computer in the monitoring center sends reading instructions to the wireless data transmission terminal (DTU) of the data acquisition terminal through the wireless communication module and with the help of GPRS transmission network. According to the instructions of the monitoring center, the wireless data transmission terminal DTU of the terminal instructs the intelligent potential measurement module to conduct real-time potential measurement, and then transmits the results back to the monitoring center through GPRS transmission network. The main functions of the system can be summarized as follows: ① data receiving and processing: receiving the protection potential of steel pipe pile at telemetry point in real time and making reasonable judgment; ② Answer query: regularly or manually query the cathodic protection of steel pipe piles; ⑧ Database management: formation, retrieval and query of original and historical databases; ④ Data output: potential statistical chart can be output through display, printer, plotter and other equipment; ⑤ Network communication: multi computer communication can be realized. In case of strong electromagnetic interference, the system can automatically return to normal operation and reduce the maintenance workload of users.

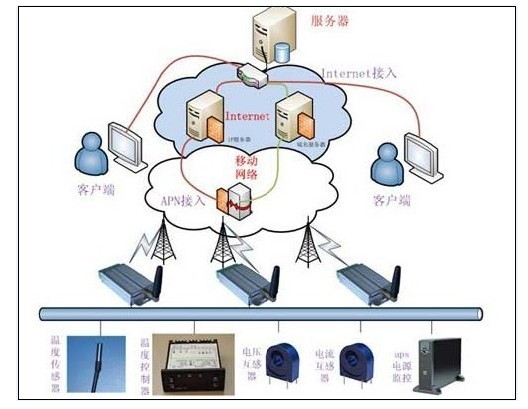

2.2 monitoring center

The monitoring center consists of wireless data transceiver module and PC. The wireless module provides data transmission channels for remote equipment monitoring, control, remote meter reading and other applications. It can not only use GPRS network provided by China Mobile Communication Company for data transmission, but also use short message (SMS) for data transmission. Users can choose GPRS channel or SMS channel according to the actual situation, and can switch between the two channels at any time.

2.3 data acquisition terminal

The data acquisition terminal is installed at each measuring point as required to collect the information of protection potential respectively. The terminal software realizes the initialization of each module, IP address and port setting of the monitoring center, communication task, condition monitoring, data processing and other functions. The program adopts modular design, which is composed of data acquisition module and wireless module. The serial communication between the two modules is based on RS232 protocol. The data acquisition module measures the field protection potential, transmits the measurement results to the wireless module, and then transmits them to the data processing center through the wireless network through the wireless module.

Main hardware equipment GPRS DTU:

Industrial GSM / gprs modem jy-md:

Industrial GSM / gprs modem jy-md is a dial-up Internet access device based on mobile GSM / GPRS network platform and embedded with industrial GSM / GPRS wireless module. The product is specially designed for the complex environment of industrial site through RS-232 or RS-485 interface Use a simple at command interaction interface, so that users face the at command interface based on serial communication, which can complete end-to-end reliable data communication.

Standard RS232 or RS485 interface;

(1) Support standard at instructions;

(2) Support short message and dialing for data transmission;

(3) Industrial power supply: dc7v ~ dc30v, built-in power reverse protection;

(4) Industrial wireless module: embedded German Siemens wireless module, strong anti-interference and stable transmission;

(5) Metal shell: metal shell is adopted to prevent radiation and interference; Lightning protection design; Meet the requirements of power safety regulations;

(6) All wireless modules have passed CGD certification or FCC certification or CE certification.

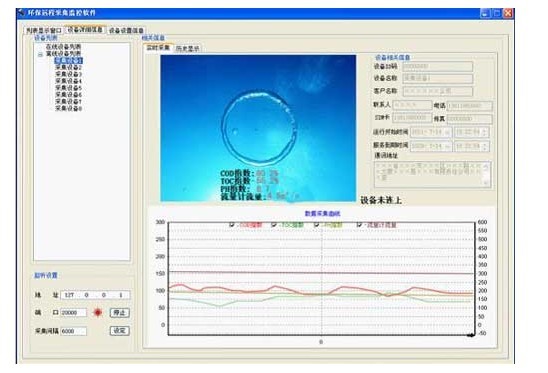

Monitoring software interface:

The device list on the left shows the information of current online and offline devices. When the device is connected to the network, it will enter the "online device list" from the "offline device list". If the device is not online for a long time, it will enter the "offline device list" from the "online device list";

The upper right corner displays the equipment number, user name, contact person, operation date, system service expiration date, telephone, fax, mobile phone, address, SIM card number and other information;

The upper left corner shows the corrosion state index;

The corrosion state index and other curves are displayed in real time under the window;

The middle text prompts the current equipment login time and the last time of collecting and returning data;

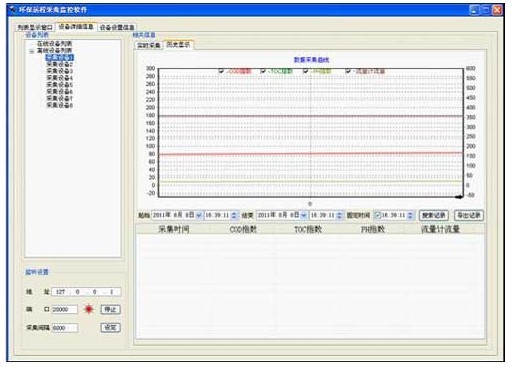

Historical records

1. Users can search history according to time period;

2. The history record will be drawn on the window in the form of curve, and the history record can be displayed under the window in the form of list. Through the history record, the equipment operation status and relevant trend can be viewed;

3. The history records queried at the same time can be exported to excel;

This wireless telemetry system based on mobile communication wireless network has the characteristics of high precision, high reliability, ultra long-distance transmission, low power consumption, high degree of automation, wide network coverage, convenience and flexibility. The probability of reliable data measurement is close to 100%, and the system has fully achieved the expected function.

3. Concluding remarks

The corrosion remote monitoring system based on GPRS DTU integrates advanced wireless mobile communication technology and electronic computer technology, which can realize the remote monitoring of the corrosion of marine steel structures, provides technical support for the corrosion disaster early warning system of marine steel structures, and has high popularization value in the field of corrosion disaster monitoring of marine steel structures in China.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts