1、 System overview

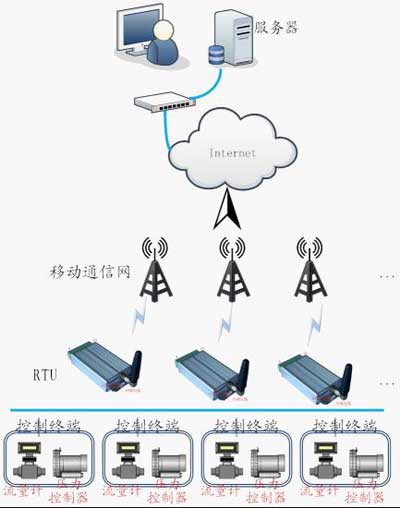

Liquid oxygen remote monitoring system is an automatic network management system combining software and hardware. The system design is to install a flowmeter on the equipment to collect the output pressure, temperature, instantaneous flow and cumulative flow of liquid oxygen; The storage tank capacity, tank liquid level and tank pressure are collected by 4-20mA differential pressure gauge and pressure controller respectively, uploaded to the server through RTU and GPRS, and the automation and integration of liquid oxygen management and monitoring are realized by Juying electronic engineer.

In 2012, our company has successfully designed the storage tank information management system for shell unified Beijing plant, which has been put into use and operated well, and has won the praise of shell unified Beijing company.

2、 System composition

1. The system is mainly composed of the following parts:

Monitoring center: computer and liquid oxygen monitoring system software;

Communication network: communication network platform based on mobile or Telecom;

Rtu4100: collect the signals of liquid oxygen flowmeter, 4-20mA differential pressure gauge and pressure controller and transmit them to the monitoring center through GPRS network;

Measuring instruments: liquid oxygen flowmeter, 4-20mA differential pressure gauge and pressure controller;

2. System structure diagram:

System structure diagram of liquid oxygen storage tank monitoring scheme

3、 Hardware introduction

1. Introduction to rtu4100:

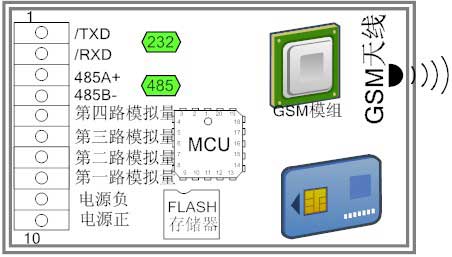

Wide voltage power supply range: 5v-30v;

With RS232 and RS485;

4 analog inputs, acquisition accuracy: 12bit

The transmission supports a variety of protocols, and our company's self-defined protocol and Modbus Protocol (ASCII, RTU, Modbus TCP) are perfectly supported;

Data transmission adopts GSM module, which can realize the following functions:

GPRS disconnection automatic reconnection;

At most multiple central servers can be connected at the same time as required;

Support the addressing mode of fixed IP, domain name resolution and APN private network;

Support TCP, UDP and other protocols;

The number of supported nodes is theoretically unlimited as long as the server resources allow;

Reduce the cost of wiring and the trouble of construction;

Support SMS data transmission and SMS parameter configuration;

Support phone and SMS wake-up function;

Support special software for local and remote parameter configuration and maintenance;

Support local and remote firmware upgrade;

Four analog inputs are used to collect the signals of 4-20mA differential pressure gauge and pressure controller, the RS485 interface is used to connect the flowmeter, and the relevant data is transmitted through the grrs function of RTU, which perfectly solves the problem of unified sending and receiving of each equipment.

2. Internal structure diagram:

Internal structure diagram of liquid oxygen storage tank monitoring scheme

4、 Software introduction

1. GPRS transmission mode is adopted to communicate with the center software.

2. The system software of the monitoring center adopts Microsoft Windows platform (the genuine Windows XP software of the system and the windows database software are purchased by the demander), and the Chinese interface can facilitate the addition of new customers and the change of user data (including the name, address, contact person, telephone and storage tank capacity of the tank equipment);

3. The main screen displays various quantities in the form of list, including storage tank capacity, tank liquid level, tank pressure, flowmeter pressure, flowmeter temperature, flowmeter instantaneous flow and flowmeter cumulative flow;

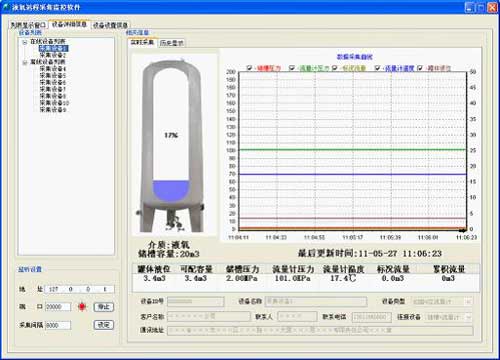

4. Each storage tank interface can display the current status information of the storage tank, customer name, address, contact person, telephone, storage tank capacity, tank liquid level, tank pressure, flowmeter pressure, flowmeter temperature, flowmeter instantaneous flow, flowmeter cumulative flow, acquisition time interval, historical trend chart, etc;

5. Lower liquid level alarm processing: after the monitoring center collects the data, it will automatically update the data. When there is an alarm, the color change of the corresponding tank list and the alarm prompt of the buzzer on the computer motherboard will be generated.

6. Report data export function;

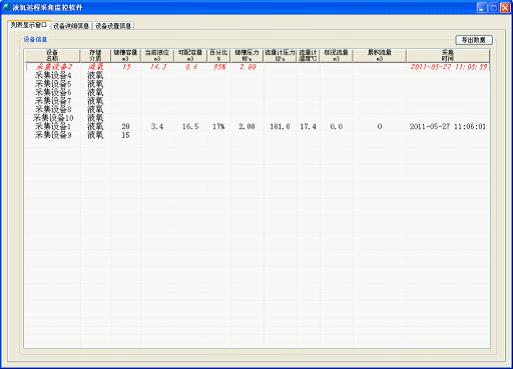

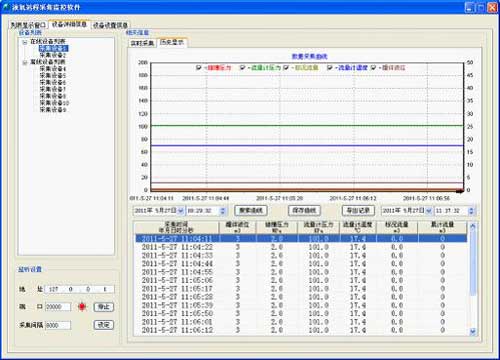

The final software screenshot is as follows:

1 - list preview interface

It mainly displays the equipment name, storage medium, storage tank capacity, current liquid level, configurable capacity, percentage, storage tank pressure, flowmeter pressure, flowmeter temperature, standard condition flow, cumulative flow, acquisition time and other information of each equipment. When the liquid level of the storage tank is lower than 10% or higher than 90% of the capacity of the storage tank, the relevant data turns red, and click to go to the detailed information of relevant equipment.

Liquid oxygen storage tank monitoring scheme cloud platform management interface

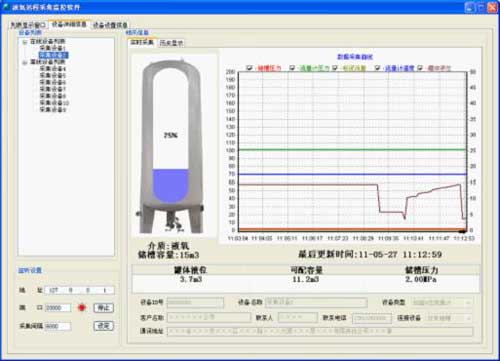

2 - real time display and history display

It mainly displays the storage medium, storage tank capacity, current liquid level, configurable capacity, percentage, storage tank pressure, flowmeter pressure, flowmeter temperature, standard condition flow, cumulative flow, acquisition time and other information. The display status is also different due to several situations.

Liquid oxygen storage tank monitoring scheme cloud platform history

There is a real-time display interface for both storage tank and flowmeter

Liquid oxygen storage tank monitoring scheme cloud platform real-time interface

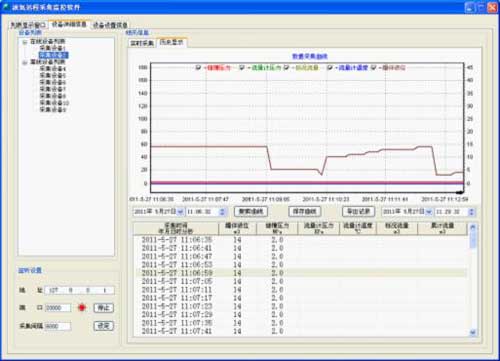

Real time history curve interface exists in both storage tank and flowmeter

Liquid oxygen storage tank monitoring scheme cloud platform history curve interface

History display interface of storage tank only

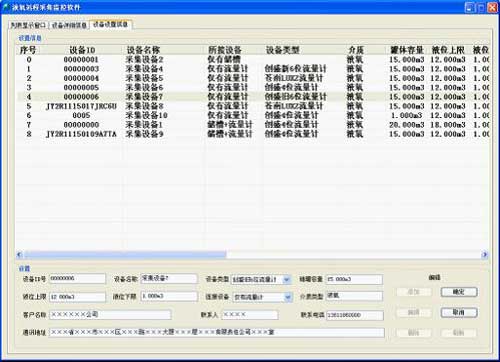

3 - device setting information

It is mainly used to set the equipment ID, equipment name, connected equipment, equipment type, medium, tank capacity, upper liquid level limit, lower liquid level limit, customer name, contact person, contact telephone, communication address and other relevant information of the equipment. The equipment setting information can be added, modified and deleted.

5、 System characteristics

Strong real-time performance, which can achieve the purpose of real-time monitoring;

Wireless GPRS network is adopted, which reduces the wiring cost, can better expand the network and is conducive to the expansion of the system;

The system is fully customized, taking into account the needs of users.

6、 System application

The system can be applied to the related detection fields of various gases.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts